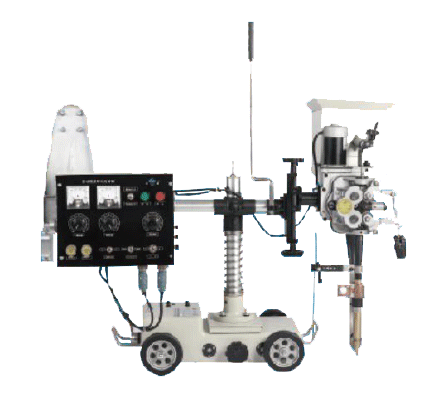

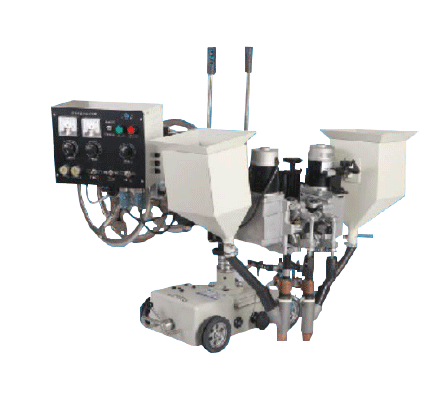

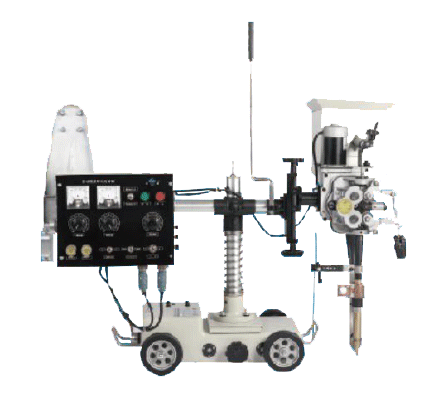

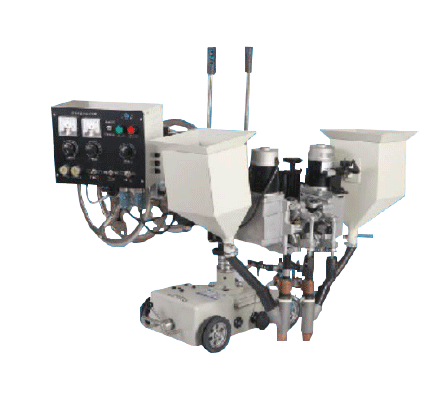

Optional Tractors

AT-1  |

AT-2  |

AT-3  |

|---|---|---|

AT-4  |

AT-5  |

AT-6  |

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号

AT-1  |

AT-2  |

AT-3  |

|---|---|---|

AT-4  |

AT-5  |

AT-6  |

Get updates on sales specials and more

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号